HOME » Product List » Digital Servo Liner

Sanyu will comply with your requests as a canmaking industry specialist.

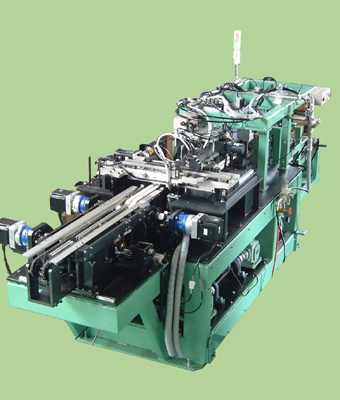

In this system, four top or bottom 18L square can ends are lined with compound simultaneously. Following lining, the compound application is automatically inspected, and defective products are ejected.

| Production speed | 120 ends/minute(standard) |

|---|---|

| Application method | 4 ends simultaneously, via two lanes |

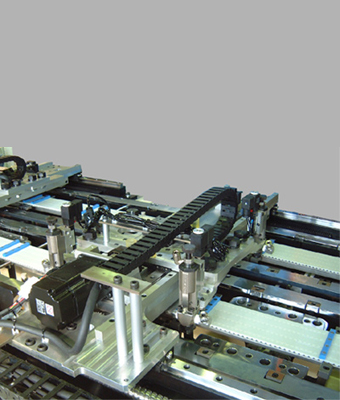

| XY gun control method | 2-dimensional servo driven control |

| Nozzle track precision | Within +-0.1 mm |

| Nozzles (4) | -Nozzle material: carbide |

| Tank | 20L - 60L |

| Work piece transport method | Servo-driven indexed transport |

| Inspection mechanism | Detection of compound width and breaks in lining, by laser sensors. |

| XY laser sensor control method | 2-dimensional servo-driven control separate servo-system from gun) |

| Defective product ejection | Each lane with separate ejection and stacking systems |

In the system,small sized square can ends are lined with compound simultaneously.

| Production Speed | 60ends/min. |

|---|---|

| Application Method | 2ends simultaneously, via 1 lane |

| XY gun central method | 2 dimensional servo driven control |

| Nozzle track precision | Within +-0.1mm |

| Nozzle (2) | Material : Carbide |

| Tank | 40L pressure tank |

| Trabsport method | Servo drive |

| Positioning method | Chuck |

| Application | ~8Kg-cans |

| Changing of tooling | Within 10 minutes |

Copyright © 2009-2013 Sanyu Machinery Co. Ltd. All Rights Reserved.